Week

of August 22, 2005

Give

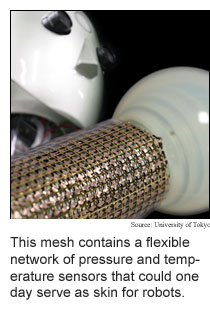

it some skin

Consider a humanoid robot in your home. Would you trust it toput

away the dishes, hang a mirror, brush the dog or boil water on the stove?

One of the key differences between humanoid robots as they exist today

and humans is skin that is sensitive to pressure and temperature.

Researchers from the University of Tokyo have developed a method

for making flexible

plastic mesh that contains pressure or temperature sensors at each

junction. The technique could lead to artificial skin with sensitivities

comparable to those of human skin. The technique also enables multiple

meshes containing different types of sensors to be laminated together.

A multiple-mesh skin could give robots not only sensitivity to pressure

and temperature, but also to light, humidity, strain and ultrasound.

Researchers from the University of Tokyo have developed a method

for making flexible

plastic mesh that contains pressure or temperature sensors at each

junction. The technique could lead to artificial skin with sensitivities

comparable to those of human skin. The technique also enables multiple

meshes containing different types of sensors to be laminated together.

A multiple-mesh skin could give robots not only sensitivity to pressure

and temperature, but also to light, humidity, strain and ultrasound.

(Conformable, Flexible, Wide-Area Networks of Pressure and Thermal

Sensors with Organic Transistor Active Matrixes, Proceedings of the

National Academy Of Sciences, August 23, 2005)

Fast nanotube fabrics

Carbon nanotubes are stronger than steel and have useful electrical

and optical properties, making them a prime candidate for all sorts of

strong, light, intelligent materials. The challenge to seeing the tiny

tubes through to their potential is making materials from them in bulk

in a way that preserves all the useful properties.

Researchers from the University of Texas at Dallas and the Commonwealth

Scientific and Industrial Research Organization (CSIRO) in Australia have

developed a commercially viable method

of manufacturing 5-centimeter-wide sheets of carbon nanotubes at a rate

of 7 meters per minute. Meter-long samples a thousand times thinner than

human hair are transparent, conduct electricity, absorb microwaves and

emit light. Potential applications include solid-state lighting, solar

cells, displays, and antennas built into car windows.

(Strong, Transparent, Multifunctional, Carbon Nanotube Sheets,

Science, August 19, 2005)

Domesticated algae

Throughout history, humans have used beasts of burden. As scientists

working in microscopic realms shift from exploring to exploiting, what's

old could become new again.

Scientists at Harvard University have attached

plastic beads to microorganisms and directed the movement of the tiny

organisms to cause them to transport the beads. The researchers burdened

one-celled algae that swim toward dim light and away from bright light

with beads as large as six thousandths of a millimeter. The method calls

for chemically attaching beads to the algae, using light to direct the

motion of the organisms, then detaching the beads at the destination using

ultraviolet light.

The tiny beasts could be used as power sources and transporters

in microfluidic devices.

(Microoxen: Microorganisms to Move Microscale Loads, Proceedings

of the National Academy Of Sciences, August 23, 2005)

Bend, but don't slow down

The possibilities of rollup displays and bendable electronic gadgets

have focused much attention on making circuits from plastic. Although

an impressive feat, today's prototypes are slower than the silicon devices

that have been widely used for decades.

As it turns out, however, flexibility doesn't necessarily require

the circuits themselves to be plastic, just the substrate they occupy.

Researchers at the University of Illinois at Urbana-Champaign have developed

a method

of printing microscopic gallium arsenide wires onto plastic surfaces shows

that circuits made from traditional high-speed metal and semiconductor

materials can be made to bend.

The high-speed flexible circuits could be used in communications

devices, space systems and flexible displays.

(Bendable GaAs Metal-Semiconductor Field-Effect Transistors Formed

with Printed GaAs Wire Arrays on Plastic Substrates, Applied Physics

Letters, August 22, 2005)

Bits and pieces:

A robotic

bat head emits and detects ultrasound, and even has movable ears;

a method of slowing

and speeding light traveling through optical fiber; and a prototype

fuel cell powered by coal.

RSS Feeds: News Blog Books New: TRN's Internet Services TRN's Jobs Center News: Research News Roundup Research Watch blog Features: View from the High Ground Q&A How It Works Buy an ad link |

|

| Advertisements: |

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|