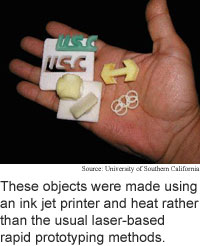

Inkjet goes 3D

Just as color printers are becoming status quo, a new

technology may enable something more -- three-dimensional desktop printers.

Three-dimensional printers use high-intensity lasers to harden

extremely thin layers of liquid plastic or melt and fuse metal or plastic

powders to build up three-dimensional forms, and are used in industry

for both rapid prototyping and manufacturing. Lasers are relatively expensive

components, however.

Researchers from the University of Southern California have fashioned

a printer that makes three-dimensional forms without the use of a laser.

Instead of using a laser beam to selectively melt material, the

researchers' selective inhibition sintering method uses an inkjet nozzle

to treat portions of a powder with an anti-sintering agent like saltwater

so that it resists melting, then exposes the entire form to high-intensity

heat.

The selective inhibition sintering method is faster than laser

methods, uses less energy, and uses much cheaper components, according

to the researchers.

The researchers used their prototype 3D printer to build forms

using layers one-tenth of a millimeter thick. Each layer can be completed

in as few as 15 seconds. The prototype is accurate to within two-tenths

of a millimeter, and could be improved using a commercial quality printhead,

according to the researchers.

The technology has been licensed to build a commercial machine,

and could be used practically within a year, according to the researchers.

The work appeared in Issue 1, 2003 of Rapid Prototyping Journal.

Robot automates science

Chemicals map nanowire arrays

Badge controls displays

Neural-chaos team boosts security

Briefs:

Inkjet goes 3D

Nanotubes tied to silicon circuit

Micro tweezers have ice grip

Nanorings promise big memory

Protein orders semiconductor bits

Technique detects quantum state

Research Watch blog

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2011. All rights reserved.