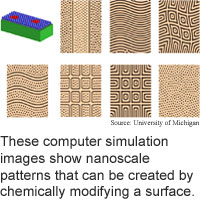

Simulation maps nano patterns

Microscopic machines promise to be useful

in manufacturing materials molecule-by-molecule and eventually for applications

like targeted drug delivery. But to construct a nanoscale machine you

must figure out how to fabricate parts that are not much bigger than molecules.

Researchers from the University of Michigan have used a computer

simulation to develop a method of chemically building nanoscale patterns

on a surface. The patterns, which include neatly-positioned groups of

wavy and straight lines, dots, boxes within boxes, and mixes of dots and

lines, would be relatively inexpensive to produce and could form the basis

for nanoscale machines.

To make the patterns, the researchers simulated the application

of monolayers, or single-molecule layers of material, to an elastic substrate.

Different materials self-assembled into different patterns. A partial-monolayer

of oxygen on a monolayer of copper, for instance, forms regular, 10-nanometer

stripes of oxygen alternating with bare copper. And a mix of copper and

lead on copper forms ordered patterns of dots or stripes depending on

the mix percentages. A nanometer is one millionth of a millimeter.

Key to the process is the surface chemistry, which governs how

the atoms of the two layers interact on a uniform surface. The choice

of materials determines the type, size and alignment of the pattern.

The researchers are working to expand the method to fabricate

more complicated structures.

The process could be used practically in two to five years, according

to the researchers. The work appeared in the February 11, 2004 issue of

Nano Letters.

Net plan builds in search

Robot guided by its voice

Angle speeds plastic transistor

Sturdy quantum computing demoed

Briefs:

DNA folds into paired pyramids

Fiber spun from nanotube smoke

Material boosts thermoelectricity

Nano ribbons coil into rings

Simulation maps nano patterns

Chip-camera combo tracks viruses

Research Watch blog

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2010. All rights reserved.