Smart dust gets magnetic

One of the main challenges in making labs-on-a-chip

is finding ways to control and mix tiny amounts of liquids.

Researchers from the University of California at San Diego are

using minuscule silicon particles to carry out these tasks.

The researchers' have modified their previously developed smart

dust by trapping magnetic iron oxide nanoparticles within the silicon

particles. The particles are chemically coated so that they adhere to

water on one side, and repel water on the other side.

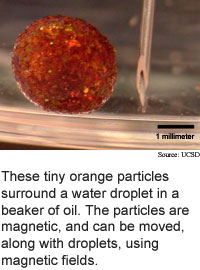

The chemical coating causes the silicon particles to surround

water droplets, and the dust changes color depending on the chemicals

it is in contact with. This allows the researchers to identify chemicals

encased by the smart dust. The magnetic properties makes it possible to

move the particles -- and the droplets they are surrounding -- using a

magnetic field.

The silicon particles are 50 to 100 microns in diameter, which

is one-tenth to one-twentieth of a millimeter.

The researchers demonstrated the system by filling and draining

droplets and by combining two droplets to carry out a chemical reaction.

The system makes it possible to work with small amounts of chemicals,

and can be automated, making it possible to carry out many reactions simultaneously,

according to the researchers.

The method could be used practically in two to five years, according

to the researchers. The work appeared in the November 7, 2004 issue of

Nature Materials.

For pure nanotubes add water

Solar cell doubles as battery

Conversational engagement tracked

Pure silicon laser debuts

Briefs:

Tight twist toughens nanotube fiber

Multicamera surveillance automated

Chemical keeps hydrogen on ice

Smart dust gets magnetic

Short nanotubes carry big currents

Demo advances quantum networking

Research Watch blog

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2010. All rights reserved.