Gels make micro plumbing

By Kimberly Patch, Technology Research NewsThe obvious difficulties of fabricating very tiny machines are the limitations of human sight and dexterity. Less obvious are the way the laws of physics at very small scales, where surface forces like static electricity loom large, making it difficult to assemble tiny parts even if you can find them.

Researchers from the University of Illinois at Urbana-Champaign are trying to sidestep the assembly problem by fabricating whole machines at once using hydrogels, which are soft polymers that change size by absorbing or expelling water when the pH or temperature around them changes.

"We set about to try using a new set of materials -- responsive hydrogels, which are quite well known from a biochemistry and polymer chemist perspective, but studied very little from an engineering perspective,” said David Beebe, assistant professor of biomedical engineering at the University of Wisconsin.

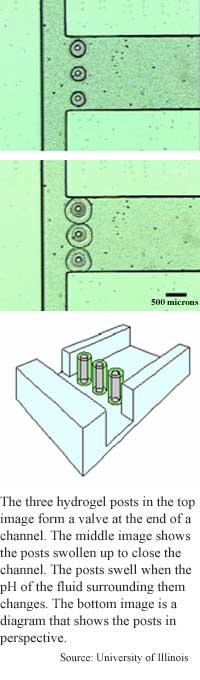

The researchers have built a microscopic valve that sorts liquids depending on the liquid's pH and a one-way valve similar to those found in human veins. A pocket botulism detector is also in the works. The machines are on the order of a couple hundred microns, which is about the width of three human hairs.

Key to building these tiny machines is that the microfluidic channels that house them are also made of hydrogel. This makes the process of building the platform and the machine analogous to building a ship in a bottle, said Beebe.

"We start with nothing and build a microfluidic channel. We flow in a polymer cocktail, we then use either laminar flow or lithography to polymerize shapes inside the channel,” he said. The polymer cocktail is hydrogel in liquid form. Using the photolithography method, the researchers fashion the shapes they want by shining ultraviolet light through a mask onto the liquid polymer, causing it to polymerize, or solidify, in the shapes defined by the mask. It takes 15 seconds to a minute for the hydrogel to solidify, said Beebe.

Once the shapes are made, the machine is done. "There's no assembly required because we build all components in place,” said Beebe.

The gel's ability to react to its environment gives the machines an automatic control mechanism. Hydrogels can change their volume by about 200 percent in response to environmental changes, compared to about 5 percent for metals. The problem is, hydrogels change relatively slowly in the macro world.

The materials have been around for two dozen years, but "haven't found widespread use... because their response time is typically very slow," said Beebe. Their response time speeds up as they get smaller, however, making the ability much more useful in the microworld. A piece of gel that is one millimeter square will take a day or two to change shape completely, but cut that down to a couple hundred microns and the response time shrinks dramatically to about 10 seconds, said Beebe

This responsiveness allowed the researchers to close the one-way valve by changing the pH of the liquid flowing through it. The flow sorting valve changes the flow direction depending on pH.

"Working with hydrogen gels that swell and shrink is an important step forward," said Mark Madou, professor of materials science and engineering, and chemistry at Ohio State University. Opening and closing small channels efficiently is difficult, he said.

Hydrogels more closely mimic the soft, environmentally responsive materials living systems use in building cells than the metals and silicon that usually make up machines, Madou added. "In our bodies we don't have any metals, we have ... membranes that are soft with little holes that open and close depending on concentration gradients and [proteins] guiding certain molecules... in and out," he said.

"We're getting closer to that with these hydrogels," Madou said. "It's not that sophisticated yet but it's definitely in the right direction," he said.

Madou's work includes combining hydrogels with metal plates and using electricity to speed their response times.

The Wisconsin researchers are also working on using the gel's ability to change size to make cheap, tiny sensors, said Beebe. Because hydrogels react directly to their environments, they can be used as tiny sensors without the addition of electronics. "[We] take a hydrogel component in a microfluidic channel, [and] build a cell-like membrane around it,” he said. When the membrane is disturbed, the gel expands, showing directly that the material the membrane is made of has been disturbed.

"We're developing a pocket detector for botulism," said Beebe. After that, the sensor could be modified to detect biological and chemical weapons as well as environmental toxins, he said.

The method could be ready to use in commercial applications in one to two years, said Beebe.

Beebe's research colleagues were Jeffrey S. Moore, Qing Yu, Robin H. Liu, Mary L. Kraft, Byung-Ho Jo and Chellnadurai Devadoss. They published the research in the December 5, 2000 issue of the Proceedings of the National Academy of Sciences. The research was funded by Defense Advanced Research Projects Agency (DARPA).

Timeline: 1-2 years

Funding: Government

TRN Categories: Microelectromechanical Systems

Story Type: News

Related Elements: Technical paper, "Microfluidic Tectonics: A Comprehensive Construction Platform for Microfluidic Systems," Proceedings of the National Academy of Sciences, December 5, 2000

Advertisements:

January 3, 2001

Page One

Gels make micro plumbing

Security comes one photon at a time

Shining a new light on electron spin

Network similarities run deep

Transistor lights up

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.