Tiny wires store more

By Eric Smalley, Technology Research NewsIt's impossible to say how many angels can dance on the head of a pin, but the music they're dancing to is another matter. A pinhead-sized section of magnetic storage media made from millions of microscopic wires could hold three and half CDs worth of music.

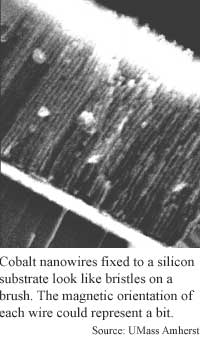

Researchers at the University of Massachusetts at Amherst and IBM Research have developed a process that yields metal wires 14 nanometers in diameter arrayed vertically on a surface. The process solves half the problem of producing disk drives that have much higher capacities.

The other half of the problem is developing a read-write head sensitive enough to make use of the media. If the technology to read from and write to an individual nanowire is worked out, the ensuing drives would hold 1.2 terabits per square inch, said Mark Tuominen, an associate professor of physics at the University of Massachusetts at Amherst. "That's about 25 DVD-quality movies on a surface the size of a quarter."

Such disks would hold 24 times more than today's state-of-the-art magnetic disk drives, which store up to 50 gigabytes per square inch.

"That's a staggering result," said Michael E. McHenry, a professor of material science and engineering at Carnegie Mellon University. "The next big goal in data storage is going to be this terabit-per-square-inch recording density."

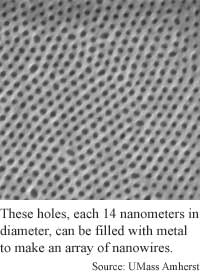

The process uses many standard chip-making techniques, including spreading a thin film of material over a silicon substrate. The film in this case is a heated mixture of polystyrene and polymethylmethacrylate (PMMA) in which the PMMA forms 14-nanometer-diameter cylinders.

"We use an electric field to orient the cylinders so they stand stick straight, like soldiers standing side by side, perpendicular to the surface," said Tuominen. The cylinders are evenly spaced about 24 nanometers apart.

The researchers cool the film to harden it, and then use ultraviolet radiation to break down the PMMA cylinders. "Wherever the cylinders were, now there's a pore from the surface to the substrate," he said.

The film is then immersed in a solution containing tiny particles of metal that fill the pores when an electric current is applied. The result is an orderly array of metal nanowires.

"Having these things periodically arranged over a large length scale is very important. You have to know where to go looking for [a] particular piece of information," said McHenry.

Making the bits perpendicular to the surface is important for fitting a lot of information in a small area. The bits in disk drive media today are parallel to the surface. The problem is researchers can't simply shrink the bits. Below about 50 nanometers, the magnetic particle that constitutes a bit has to be longer than it is wide or else it becomes superparamagnetic.

If a particle is superparamagnetic thermal energy from the environment can change its magnetic orientation, meaning the bits become unstable and can flip. Orienting the bits perpendicular to the surface allows researchers to keep them large enough to be stable while fitting more of them in the same surface area, said Tuominen.

Another important part of the project was to develop a process that can easily scale up for mass production, Tuominen said. "It was important to make arrays [that were] spun cast onto a surface," similar to the way light-resistant material is applied to put on silicon surfaces in chip making, he said. "This is quite straightforward and adaptable to industrial processes."

The researchers have used the process to make cobalt, copper, gold and cobalt-copper nanowires. They used a similar process to make silicon oxide pillars. Silicon oxide is an insulator and structural element in computer chips and other silicon devices.

The researchers have also used electron beam patterning to make nanowire arrays on specific portions of a surface, Tuominen said. "You can arbitrarily pattern the array quite easily."

Now the researchers are working on making smaller nanowires. "[We've] made pores as small as five nanometers, but that's still a work in process," Tuominen said.

The arrays could also be used to produce high-density memory. "The underlying physics... is not completely established... but there is some promise to possibly use these for a type of MRAM. Many hurdles have to be overcome before that's a reality," said Tuominen. Magnetic Random Access Memory, which uses magnetism rather than electric charges to store bits, and is likely to be the next generation of computer memory. MRAM will be faster and more dense than today's memory and will retain data after the computer is turned off.

Because the process is compatible with existing manufacturing techniques, it could be adopted in less than a year, said Tuominen.

Tuominen's research colleagues were Thomas Thurn-Albrecht, Jörg Schotter, Gerd A. Kästle, Nathan Emley and Thomas P. Russell of UMass Amherst, and Takasada Shibauchi, Lia Krusin-Elbaum, Kathryn Guarini and Charles T. Black of IBM Research. They published the research in the December 15, 2000 issue of Science. It was funded by the National Science Foundation and the Department of Energy.

Timeline: <1 year

Funding: Government

TRN Categories: Semiconductors and Materials; Data Storage Technology

Story Type: News

Related Elements: Technical paper, "Ultrahigh-Density Nanowire Arrays Grown in Self-Assembled Diblock Copolymer Templates," Science, December 15, 2000

Advertisements:

December 20/27, 2000

Page One

Tiny wires store more

Tinier transistors keep Moore's Law on track

3-D geometry adds twists to microfabrication

Virtual annotation fosters understanding

Silicon process produces pockets

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.