Metal

crystals cover glass

By

Kimberly Patch,

Technology Research NewsOne of the challenges of materials science is getting unlike substances to adhere to one another.

Researchers from a pair of French universities have found a way to put metal coatings, which conduct electricity, on materials like glass and plastic, which insulate rather than conduct. The researchers coaxed a flat layer of metal crystals, or dendrites, to grow on glass or plastic surfaces by immersing the insulators in a solution containing the metal, and applying the right amount of electrical current.

Many types of electronics and optics are made of layers of material that include insulators and metals. The researchers' process could eventually be used in electronics, to make mirrors of unusual metals and shapes, and to directly coat organic materials with metal, said Vincent Fleury, a researcher at École Polytechnic University and the French National Center for Scientific Research (CNRS).

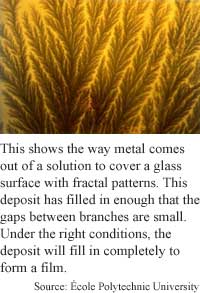

The researchers' key discovery was realizing that metal dendrites, the frost-like patterns of metal coming out of the solution, could be coaxed to completely cover a flat surface. In studying metal dendrite growth "I discovered that the deposit would become more space-filling, and completely covering instead of dendritic, for the higher values of the current," said Fleury. The higher the electrical current the denser the patterns became, he said.

When the patterns completely fill in, the quality of the coating is good enough to reflect light, said Fleury. "I can actually make mirrors -- of a small size... but good mirrors," he said. The researchers have deposited silver, copper and tin on insulators including glass and Teflon.

In order for the coating to grow properly, the surface must be very clean, Fleury said. "The main challenge is to have a glass plate clean at the molecular level," he said. Another challenge is making sure the insulator is free of scratches. "The growth is much more rapid in scratches," which destabilizes the growth process, said Fleury.

Although the method works directly on insulators, it works more easily over a seed layer, said Fleury. "The trick is to start the deposition at the surface [with] a bait. You can use silver paint, or a gold layer. Then it grows along the surface in a reasonably wide range of currents and of concentrations," he said.

The crystal layer grows at a rate of about 100 microns per second, Fleury said. The researchers have demonstrated the non-seed layer process on narrow samples like glass and Teflon fibers, and with the seed layer method they have coated glass with a strip of silver as long as two centimeters, he said.

Electrochemical processes in general can be scaled up for manufacturing fairly easily, said Fleury. The more difficult steps in the process are preparing the surface and checking the quality of the deposit. The process is also relatively slow, said Fleury.

In theory, the process could even be used to coat something living, like a leaf, with metal, said Fleury. "I think one could metallize a flat living being alive, because you can dip it for a while in copper sulfate [and] it will survive," he said.

Growing three-dimensional metal dendrites is a common way to make metal powders from solution. In this process, the dendrites are not stable and easily collapse into powder. The two-dimensional metallic layer process, can, in addition to producing uniform film, be used to preserve the dendrite patterns, which are fractals, said Fleury. Fractals are mathematically balanced patterns made by successive subdividing, so that a larger portion of the pattern and a smaller portion look alike.

The researchers' method preserves the deposit "in the way it was grown... as [a] tree-like structure," said Fleury. "These trees might have applications," he said.

Fleury's research colleagues were Wesley A. Watters of École Polytechnic University and CNRS, and Levy Allam and Thierry Devers of the University of Orleans at Chartres. They published the research in the April 18, 2002 issue of the journal Nature. The research was funded by the French National Center for the Scientific Research (CNRS).

Timeline: <1 year

Funding: Government

TRN Categories: Materials Science and Engineering

Story Type: News

Related Elements: Technical paper, "Rapid Electroplating of Insulators," Nature, April 18, 2002.

Advertisements:

May 1/8, 2002

Page One

Team spins mirror fibers

Light flashes fire up nanotubes

Quantum force powers microslide

Light boosts plastic magnet

Metal crystals cover glass

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.