Microwave

drill melts concrete

By

Eric Smalley,

Technology Research NewsCross a microwave oven with a nail and you get a drill that makes holes by melting the material in its path.

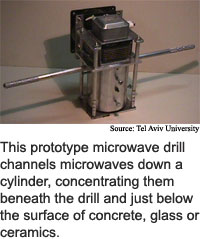

Researchers at Tel Aviv University in Israel have made a prototype microwave drill that can make a 2-millimeter-diameter, 2-centimeter-deep hole in concrete in about a minute.

The microwave drill is quiet, doesn't produce dust, and is less expensive to make than laser drills, said Eli Jerby, an associate professor of physical electronics at Tel Aviv University in Israel. Once the drill is optimized, it should work as fast as mechanical drills, he said. The principal behind the drill can be used to make other tools as well, he said.

The drill works on materials like ceramics, concrete and glass, which tend to absorb microwaves, but doesn't work on conductors like metals, which reflect microwaves, said Jerby. It could be used in production lines in the electronics, automobile, ceramics, glass and construction industries, and for geological applications, he said.

The drill bit serves as an antenna to focus microwave energy on a small spot under the surface of the material, and the intense microwave energy rapidly melts the material in this spot, said Jerby. Instead of spreading microwave energy over the entire chamber of a microwave oven, "we... compress the energy into a much smaller volume -- less than 1 cubic centimeter," said Jerby. The temperature within the small spot rapidly exceeds 1,500 degrees Celsius, which is hot enough to melt many materials.

This heating happens rapidly because of the thermal runaway effect, Jerby said. The effect begins when the focused microwaves, which are 122 millimeters long, produce a 1-millimeter hot spot. The intense heat modifies the properties of the material in the hot spot so that it absorbs the microwaves even more readily. This "further localizes the heating in an exponential growth, leading to an extremely high temperature in a small spot," said Jerby.

Once a hot spot is created, the microwave drill pushes into the softened material, and moves the hot spot forward, said Jerby. The bit moves through the material like a hot knife going through butter, he said.

The concept that led to the drill was the idea to produce a localized thermal runaway effect on purpose, said Jerby. The thermal runaway effect is usually undesirable, he said.

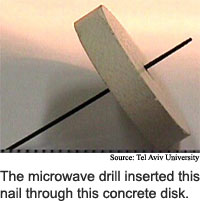

Useful applications of the effect are not limited to drilling, said Jerby. "Derivatives of the microwave drill could be used for cutting, nailing, jointing or just for local heating," he said. The researchers have used the drill to insert metal pins into hard materials, for example, said Jerby. "One can use the microwave drill to replace three successive operations -- drilling, nailing and gluing." Nailing is accomplished by leaving the bit in the material, and when the softened material cools and hardens, it glues the nail in place.

The main disadvantages of the device are that it could be a radiation hazard and it can produce heat stress effects like cracks, said Jerby. These make the drill appropriate only for professional workers and automatic production lines and not for do-it-yourselfers, he said.

Under normal operations, the radiation hazard posed by the drill is comparable to that of a microwave oven, Jerby added. "We [have] reached this safety level in our lab," he said.

The cost of a drill made from microwave oven components is comparable to the cost of a mechanical drill, said Jerby. However, it's more likely that commercially available microwave drills will be more expensive versions tailored for specific applications, he said.

The researchers' prototype is about 30 centimeters tall. Inside the drill is a 5 to 30 millimeter diameter cylinder encompassing the drill bit. The bits range from 0.3 to 6 millimeters in diameter.

The idea of the microwave drill appears sound and is relatively novel, said James R. Thomas, a professor of mechanical engineering at Virginia Polytechnic Institute. There are niche applications where it could be competitive with other types of drills, said Thomas. However, "it would be limited to relatively small holes and it will not be as precise as a laser drill," he said.

The researchers next steps are working on ways to prevent the drill from inducing thermal stress effects like cracks, dealing with safety issues, adapting the drill to make larger and smaller holes, studying materials-related effects produced by the drill, and developing derivative devices, said Jerby.

The microwave drill could be used in practical applications today, said Jerby. "We have working prototypes for ceramic materials, concrete and glasses," he said. "These can be industrialized within one to two years."

Jerby's research colleagues were Vladimir Dikhtyar, Oleg Actushev, and Uri Grosglick. They published the research in the October 18, 2002 issue of the journal Science. The research was funded by Tel Aviv University.

Timeline: Now

Funding: University

TRN Categories: Materials Science and Engineering

Story Type: News

Related Elements: Technical paper, "The Microwave Drill," Science, October 18, 2002

Advertisements:

October 30/November 6, 2002

Page One

Nanoscale LED debuts

Data transfer demo sets speed mark

Pulling nanotubes makes thread

Text software spots intruders

Microwave drill melts concrete

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.