Painted LEDs make screen

By

Kimberly Patch,

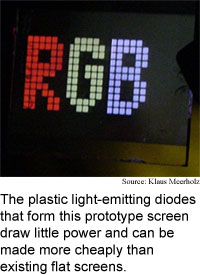

Technology Research NewsA research team from Germany has developed a process for producing plastic, full-color flat screen displays that is simpler and potentially cheaper than today's manufacturing methods for organic light-emitting diode screens.

The researchers made the displays by spreading light-emitting plastic, or polymer, molecules on a surface and exposing the polymers to spots of ultraviolet light.

The method could produce color screens that are comparable in quality to current flat screens, but are more rugged and require less power, according Klaus Meerholz, who conducted the research at Munich University in Germany and is now a professor of physical chemistry at the University of Cologne. The method allows for "flat panels with high brightness, extremely large viewing angle, and fast switching times," he said.

The method is "really fantastic," said Yang Yang, a professor of materials science and engineering at the University of California at Los Angeles. "The idea... has been discussed for years," he said. "However, the device performance is always much poorer than... traditional devices." The researchers did an excellent job of pushing the device performance to a practical level, he said.

The researchers' prototypes produced pixels of comparable size, sharpness and thus resolution as today's state-of-the-art flat screens. The method has the potential to produce even smaller pixels, which would make for screens of higher resolution than today's models, according to Meerholz.

The process is also "much simpler" than existing flat-screen manufacturing methods, said Meerholz. This could translate into cheaper and more rugged full-color screens for devices like cell phones and laptops.

The process could also be used to pattern polymers to make electronic devices like transistors, sensors, and even wires, said Yang.

Key to the method is a polymer molecule that emits light and also has photoresist properties. Photoresists are soluble in water, but shining ultraviolet light on them causes the polymer molecules to each other, rendering them insoluble.

This property allowed the researchers to pattern the polymer into the separate, tiny dots, or pixels needed to produce a screen. The researchers spread the polymer on a surface, shined ultraviolet light through a shadow mask that contained 125-micron holes, then washed off the polymer that was not cured. A micron is one thousandth of a millimeter.

By repeating the process with red-, blue- and green-emitting polymers, the researchers were able to produce a full-color screen.

The method produced sharply defined dots, and in theory could produce dots only a few microns wide, which would allow for even higher resolutions, according to Meerholz.

The process is quite promising for full-color flat-panel displays, mechanically flexible displays and, potentially for color image sensors, said David Braun, a professor of electrical engineering at California Polytechnic State University. The simultaneous control over pixel color and pixel patterning, and the ability to produce nonsoluble electroluminescent films, are novel, he said.

The researchers are currently testing the long-term stability of screens produced using the method, according to Meerholz. They are also working on producing true RGB colors, which are the standard colors displayed by computer screens.

The method could produce practical displays within two years, said Meerholz. "The technology is almost ready to go."

Meerholz's research colleagues were C. David Müller, Nina Reckefuss, Paula Rudati and Holger Frohne from Munich University, Aurélie Falcou and Heinrich Becker from Covion Organic Semiconductors in Germany and Marcus Rojahn, Valérie Wiederhirn and Oskar Nuyken from the Technical University of Munich. The work appeared in the February 20, 2003 issue of Nature. The research was funded by Covion Organic Semiconductors, the German Research Foundation (DFG) and the Bavarian Government.

Timeline: < 2 years

Funding: Corporate, Government

TRN Categories: Materials Science and Engineering; Optical Computing, Optoelectronics and Photonics

Story Type: News

Related Elements: Technical paper, "Multi-Color Organic Light-Emitting Displays by Solution Processing," Nature February 20, 2003.

Advertisements:

March 28, 2003

Page One

Painted LEDs make screen

Infrared headset nixes radiation

Fiber loop makes quantum memory

Glowing beads make tiny bar codes

News briefs:

Alcohol powers fuel cell

Sandwich promises cheap storage

Liquid crystals go 3D

Nanoscale rubber hoses debut

Biochip moves liquids with heat

Twisted nanotubes have spring

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.