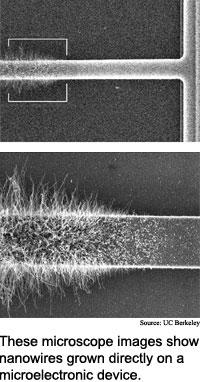

Process puts nanotubes in place

University of California at Berkeley researchers

have found a way to grow silicon nanowires and carbon nanotubes directly

on delicate microelectronic components.

The simple method promises to enable vanishingly small, relatively

inexpensive gas detectors, pressure sensors, biosensors and strain gauges

that monitor structures like airplane wings, according to the researchers.

The method could also eventually foster components for nanoelectronics

and for quantum computers, which are theoretically many orders of magnitude

faster than today's computers.

The researchers used a vacuum and resistive heating -- the warming

technology ordinary toasters employ -- to provide the 700 to 1,100 degrees

Celsius temperatures needed to form nanowires and nanotubes from a metal

catalyst and chemical vapor. The heating was restricted to a bridge structure,

keeping nearby electronic components a safe 25 degrees. Nanowires or nanotubes

formed depending on the temperature, catalyst and vapor used.

The researchers made nanowires 30 to 80 nanometers in diameter and

up to 10,000 nanometers long, and nanotubes 10 to 15 nanometers in diameter

and up to 5,000 nanometers long. A nanometer is one millionth of a millimeter,

or the span of 10 hydrogen atoms.

Simple sensors could be built within a year, and the method could

be used commercially within ten years, according to the researchers. The

work appeared in the June 30, 2003 issue of Applied Physics Letters.

DNA makes nano barcode

Study reveals Net's parts

Recommenders can skew results

Light pipes track motion

News briefs:

Material helps bits beat heat

Process puts nanotubes in place

Printing method makes biochips

Tiny T splits light

Tiny walls sprout nanowires

Big sites hoard links

Research Watch blog

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2010. All rights reserved.