Fluid chip does binary logic

By

Kimberly Patch,

Technology Research NewsToday's computer chips use the absence and presence of electrical current to represent the 1s and 0s of binary numbers and use logic gates to change these signals to match a mathematical operation.

Researchers are working schemes to carry out logic operations with microfluidic chips, which push tiny amounts of fluid through channels and are usually used to perform biological and chemical testing. The ability to carry out logic operations using liquid could be a useful part of a lab-on-a-chip.

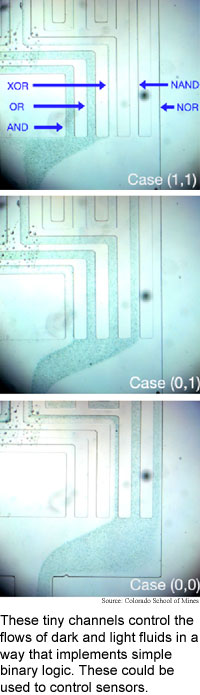

Researchers from the Colorado School of Mines have constructed microfluidic gates that use the relative flow resistance of liquid to carry out the basic logic operations NOT, AND, OR, XOR, NOR and NAND. The researchers have also combined a pair of gates into a half adder, which carries out half the operation of addition.

If the researchers are able to combine many gates to make a microfluidic computing system, the technology could lead to inexpensive, easily-manufacturerd handheld labs-on-a-chip that do not require control electronics, said Tor Vestad, a researcher at the Colorado School of Mines.

Logic gates convert one or two inputs into an output based on a rule. A NOT gate changes an input of 0 to an output of 1 and vice versa. An AND gate uses two inputs, and returns an output of 1 if both inputs are 1. An OR gate returns a 1 if either or both inputs is 1. An XOR gate returns a 1 if either of two inputs are 1. NAND and NOR return the opposite of AND and OR.

The researchers' current half adder prototype uses the same inputs for an AND and an XOR gate. "Because we can make several gates at the same time from one set of inputs we [can make] a half-adder," said Vestad.

The researchers' microfluidic logic gates convert "flow" or "not flow" inputs to outputs of "dyed" or "not dyed" liquid. The logic gates take advantage of a key characteristic of very small channels: lack of turbulence, which makes mixing liquids more like kneading dough than stirring cream into coffee. This makes it possible to flow clear and dyed streams through intertwining channels without mixing them.

The NOT gate, for instance, consists of two streams, a clear signal stream and a dyed constant stream.

When the clear signal stream is open, it feeds into the output signal stream, which confines the dyed constant stream to a waste output channel. When the signal stream is closed the constant stream broadens to both outlets, filling the output signal stream with dye. The signal stream represents an output of 0, and the dyed output stream represents an output of 1.

The NOT gate is the simplest logic gate because it only has one input and so all the channels can be flowing at the same rate, said Vestad.

Making the two-input logic gates required finding a way to precisely control relative flow regardless of the overall flow rate, said Vestad.

The researchers took advantage of a property of fluids: for any channel of a given size the resistance to flow is proportional to the length of the channel. "This means that as long as the cross sections are the same for all the channels, the relative flow rates of channels in parallel are proportional only to their length," said Vestad.

To make the two-input logic gates, the researchers adjusted the channel length. "We calculated how much relative resistance each output channel needed to have in order to function as a specific type of gate, and then just made our channels the proper length to achieve that," said Vestad.

Combined with the lack of mixing, the method made it possible to predict exactly where the dye would go regardless of how fast the fluid was moving, said Vestad.

The work is aimed at keeping microfluidic systems small, said Vestad. "Currently most microfluidic control systems require significant amounts of macro equipment: pumps, pneumatic controls and large optical setups are required to get information into and out of the microscale" devices, he said.

The proof-of-principle devices have two shortcomings: switching inputs between 1 and 0 requires manually pinching off channels, and, because inputs use presence and absence of flow while outputs use two types of fluids, the logic gates can't be linked. "We're working on making the inputs and outputs be of the same type," said Vestad. "This would allow us to link the gates together and make more complex systems, including a full adder, which requires taking the output from the AND gate of the half adder as an input to another half-adder."

If this proves possible, the passive control system could lead to simple handheld microfluidic systems that incorporate all necessary components in one unit, without the need for external equipment or an electric power supply, Vestad said. "Once we are able to integrate many gates together we will be able to make calculations and get feedback from microfluidic systems within a passive, cheap and easily manufactured system," he said.

An all-fluidic device would have many applications, said Vestad. "Such systems might be used for everything from a home device for determining what illness is affecting a child, to making a massively parallel, disposable research system for pharmaceutical development."

It will be possible to demonstrate a simple computational system within two years, said Vestad. It will be 5 to 10 years before the technology could be used in practical microfluidic systems, however, he said.

Vestad's research colleague was David W. M. Marr. The work appeared in the June 21, 2004 issue of Applied Physics Letters. The research was funded by the National Aeronautics and Space Administration (NASA) and the National Science Foundation (NSF).

Timeline: 2 years, 5-10 years

Funding: Government

TRN Categories: Microfluidics and BioMEMS

Story Type: News

Related Elements: Technical paper, "Flow Resistance for Microfluidic Logic Operations," Applied Physics Letters, June 21, 2004

Advertisements:

October 6/13, 2004

Page One

Atomic clock to sync handhelds

Quantum math models speech

Page layout drives Web search

Fluid chip does binary logic

Briefs:

Chip spots DNA electrochemically

Crystal structure tunes nanowires

Gas flow makes electricity

Sound makes electricity for space

Design rules build on self-assembly

Nanotube diode reverses itself

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.