Biochip puts it all together

By

Eric Smalley,

Technology Research NewsScientists are working to make minuscule chemistry labs for many uses. Labs-on-a-chip promise to detect and analyze microorganisms and chemicals in the field, are potentially much faster and cheaper than today's testing methods, and could enable new types of analysis.

It isn't easy cramming all the hallmarks of labs -- the chambers and channels that hold and guide fluids, the pumps and valves that shunt fluids around, and the heaters, mixers and sensors that carry out experiments -- onto a self-contained chip that works automatically.

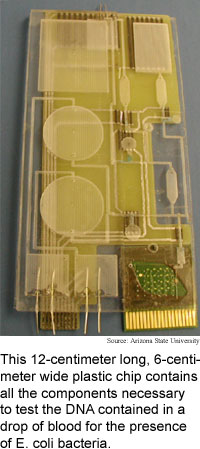

Researchers from Arizona State University have taken a large step in that direction, however, by fabricating a biochip that contains all these elements and is very cheap to produce. The plastic chip is 12 centimeters long, 6 centimeters wide and 2 millimeters thick, and uses very little power.

The chip could eventually be used in portable devices that do genetic analysis, environmental testing and biological warfare agent detection in the field, said Robin Liu, manager of microfluidic technology at the Arizona State University Applied NanoBioscience Center.

The researchers demonstrated the prototype by having it prepare and analyze a raw sample of whole blood from a rabbit. It took the device 3.5 hours to identify a disease-causing E. coli bacteria in the rabbit blood, according to Liu.

What sets the chip apart from other prototype biochips is that it carries out all the work needed to prepare a sample like whole blood, said Liu. "On-chip sample preparation [is] integrated with back-end DNA detection," he said.

The microfluidic devices that make up the chip perform all of the front-end sample preparation steps, including target cell capture using immunomagnetic beads, cell preconcentration and purification, cell lysis, DNA multiplication and electrochemical detection of low levels of DNA, said Liu. Cell lysis is the process of breaking down cell membranes, which is necessary to get at a cell's DNA. "The device is completely self-contained," he said. "No external pressure sources, fluid storage, mechanical pumps or valves are necessary."

Key to the device is its simplicity. Many microfluidic devices are made in multiple layers. In contrast, the researchers' single-layer, plastic microfluidic components are simple and inexpensive to manufacture. "Fabrication and integration [is easy] compared with multi-layer and three-dimensional structure fabrication," said Liu. These technologies are often too expensive or too complicated for mass production, he said.

Each of the biochip's components is simple, said Liu. "One example is our paraffin-based microvalves that simply use a plug of wax as an actuator." As a result, it costs less than one-tenth of a cent to add a valve to the chip, he said.

The chip contains a pair of pumps that have no moving parts. One is an air pocket attached to a heater, which expands the air to pump small volumes of liquid, and the other is a pair of electrodes that generate a current between them to carry out electrolysis, which extracts hydrogen and oxygen gas from water. This type of pump can to move larger volumes of liquid.

The chip mixes liquids by using sound waves to vibrate air bubbles trapped in small pockets in the cover of the mixing chamber. The vibrations move the air bubbles through the liquids, and friction causes the liquids to mix. Completely mixing two fluids in a 50-microliter chamber takes six seconds using this cavitation microstreaming process, according to Liu. Because such small amounts of fluids are extremely viscous, it would take several hours for the fluids to completely mix by natural diffusion.

The chip's sensor is a DNA microarray developed by Motorola Inc. that contains DNA strands attached to gold electrodes. When DNA from the target pathogen combines with the DNA on the chip, it produces an electrical signal, which indicates that a pathogen is present.

The chip also contains temperature sensors, heaters and a fluidic circuit, and has a total manufacturing cost of seven dollars, according to Liu. The cost will drop when the chip is mass-produced, he added.

The researchers are working on increasing the efficiency of the cell capture step and increasing detection sensitivity, said Liu. The technology will be ready for commercialization in two to three years, he said.

Liu's research colleague was Piotr Grodzinski. The work appeared in the October, 2003 issue of the Journal of Microlithography, Microfabrication and Microsystems. The research was funded by the Defense Advanced Research Projects Agency (DARPA) and the National Institute of Standards and Technology (NIST).

Timeline: 2-3 years

Funding: Government

TRN Categories: Microfluidics and BioMEMS; Biotechnology; Integrated Circuits; Materials Science and Engineering

Story Type: News

Related Elements: Technical paper, "Development of Integrated Microfluidic System for Genetic Analysis," Journal of Microlithography, Microfabrication and Microsystems, October, 2003

Advertisements:

December 3/10, 2003

Page One

Biochip puts it all together

DNA assembles nanotube transistor

Software paraphrases sentences

Chaotic lasers lock messages

Briefs:

Nanotubes detect nerve gas

Microneedles give painless shots

Layers promise cheap storage

Molecule makes two-step switch

Spin material handles heat

Carbon boosts plastic circuits

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.