Surfaces channel liquids

By Kimberly Patch, Technology Research NewsThe best way to make water run downhill is to make sure it starts at the top of a rise.

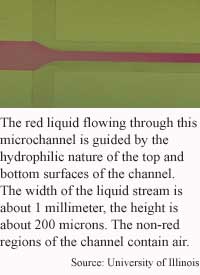

Researchers from the Universities of Illinois and Wisconsin have found a way to direct the flow of liquid inside microchannel networks of hydrogel that have no sides by making sure the path they want the water to flow through is attractive to the water.

Hydrogels are soft organic materials that can be fashioned into very small systems.

The researchers made the devices using a coating of hydrophobic, or water-repelling material. They bombarded the coating with ultraviolet light through a mask. Where the light hit the coating, the surface became hydrophilic, or water attracting.

A sandwich of two pieces of this material made a channel with no sides. The material naturally sticks together. When the researchers injected water into the system, it parted the material, but only in the hydrophilic pathways. "The water you flow in only flows where it is wanted. It is sort of like the parting of the Red Sea. Because of the strong influence of surfaces one can actually achieve such a parting at the microscale," said David Beebe, an assistant professor of biomedical engineering at the University of Wisconsin-Madison.

The channels were one or more millimeters across and 180 microns deep. There are 1,000 microns in a millimeter. The researchers also used the device as a pressure sensitive switch. Under this setup, the central region of a channel was hydrophilic, but the two sides and several perpendicular channels were modified to be less hydrophilic, requiring more pressure to pump water through those areas.

The method may eventually prove useful for mixing tiny amounts of liquids or liquids and gases in hydrogel devices and on microchips, said Beebe. "The directed flow methods make it easy to create large liquid/gas interfaces inside microchannels that could be the base of reactions or separations," he said.

Ultimately, the method gives researchers using hydrogels another tool to make the tiny systems capable of more complicated control, Beebe said.

"Our ultimate goal is low-cost, easy-to-make autonomous microfluidic systems... that require no external power supply but are still capable of complex functionality," he said. "The directed flow methods... are just one piece of the puzzle towards that final picture. Our previous work on responsive hydrogels in microchannels is another piece. Other researchers are also adding pieces to the puzzle."

The gel channels could easily be manufactured en mass, said Jeffrey Moore, a professor of chemistry at the University of Illinois at Urbana-Champaign.

The surface directed liquid flow method could be used in practical applications in close to two years, according to Beebe.

Beebe's and Moore's research colleague was Bin Zhao of the University of Illinois at Urbana-Champaign. They published the research in the February 9, 2001 issue of Science. The research was funded by the Defense Advanced Research Projects Agency.

Timeline: > 2 years

Funding: Government

TRN Categories: MicroElectroMechanical Systems (MEMS)

Story Type: News

Related Elements: Technical paper, "Surface-Directed Liquid Flow Inside Microchannels," Science, February 9, 2001.

Advertisements:

March 14, 2001

Page One

Tools cut data down to size

Ribbons expand nanotech toolbox

Silicon cages metal atoms

Surfaces channel liquids

Chip impurities make quantum bits

News:

Research News Roundup

Research Watch blog

Features:

View from the High Ground Q&A

How It Works

RSS Feeds:

News

Ad links:

Buy an ad link

| Advertisements:

|

|

Ad links: Clear History

Buy an ad link

|

TRN

Newswire and Headline Feeds for Web sites

|

© Copyright Technology Research News, LLC 2000-2006. All rights reserved.